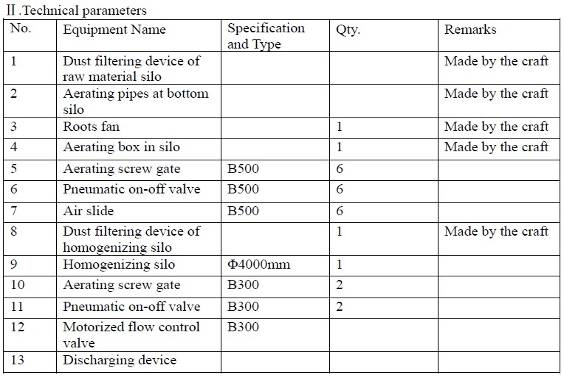

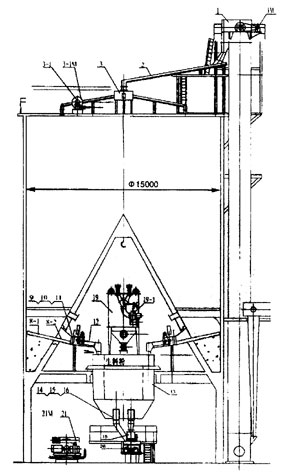

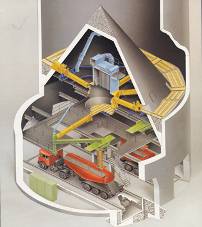

I B A U Raw Material Homogenizing Silo

Ⅰ.Brief introduction

The IBAU silo uses continuous even technology of Germany IBAU company, and is equipped with a mixing silo outside IBAU silo. A big cone is designed in the middle bottom of IBAU silo, so raw material inside silo can be transferred to silo wall from the cone relying on themselves' weights. Circular room on the bottom silo is divided into six aerating zones inclining ten degrees to the center. Every zone is assembled with aerating case. When aerating or discharging, raw material is conveyed to one radial aerating case, and then discharged through an exit on the bottom of silo and through the air slide to the mixing silo outside. During discharging process, a mixing effect of gravity formed from cutting horizontal material layer is produced with materials' falling down and a further homogenization in the mixing silo is done for materials with continuously aerating blending. The even value can reach the range of 6-8 and electricity consumption is 0.1-0.2kwh/t-raw material.