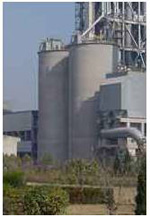

CP Raw Material Homogenizing Silo

Ⅰ. Brief introduction

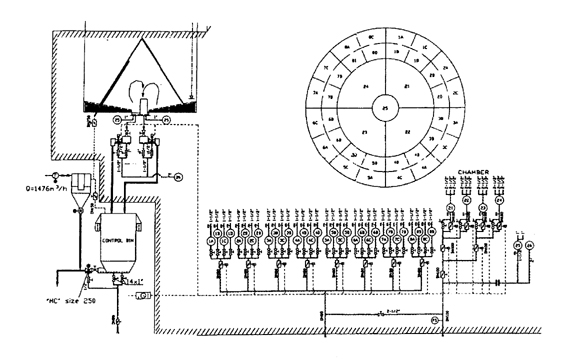

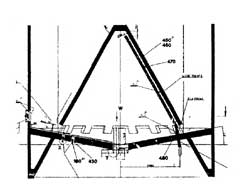

CP silo supplied from our company is a new type of even silo of a German BMH company,characterized by low power consumption and good effect of homogenization. The principle of CP silo is that the raw material at top of silo is introduced into silo evenly through eight air slide, and raw materials from different periods are stored in silo in a horizontal distribution. Aerating system at the bottom of silo is designed to assist the raw material flowing through after aerating to show an oblique and radial distribution. The ring area is divided into eight areas generally, and aerating system works alternately every five minutes. Then the raw material is disposed into the centre zone because of its loosening and leading from air flow. Thirdly raw material in different level of silo is cut vertically to achieve a homogenization of raw material. The raw material from time to time entering into the central area of silo finally is mixed by a strong gas to achieve the desired homogenized effect.

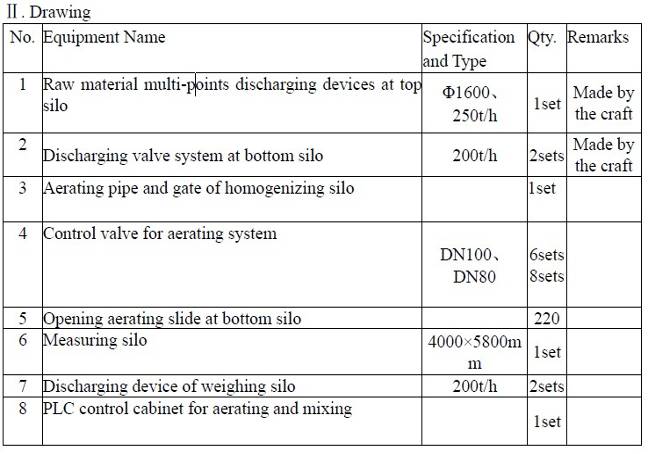

Technical parameter table

CP library schematic