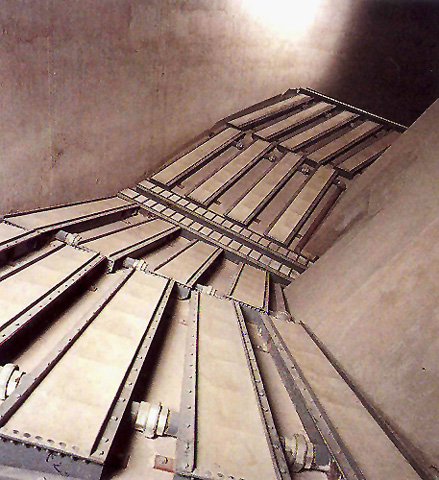

Aerating Box

Aerating box is a pneumatic even device of cement industry for feeding or mixing the powder materials. It is applied to different types of raw material silo, storing silo and mixed even silo. It has mainly four categories which are rectangular shape, right angle trapezoid, isosceles trapezoid and the special form. It is characterized with simple structure, reliable performance, no noise, easy maintenance, homogeneous mixing and so on, and is widely used in the cement industry. It is the indispensable equipment for cement production and raw material storing and mixing.

Technical performance

1, mixing material : dry powder material, allowing surface water content:〈1%;

2, ventilated property:〈3 m3/m2·min;

3, wind pressure :〈4 kg/cm2;

4, ventilated layer resistance :〈1200Pa;

5, ventilated material: synthetic polyester mixed permeability layer.

Order, shape and installation:

When considering the arrangement of aerating box in the silo, in principle, the ratio of actual arrangement area among the total area should be as big as possible. This is also important for the mixing silo and the central area of mixing even silo (mixing area). Now here six basic arrangement forms with A, B, C, D, E, F are introduced for selection. A and B types arrangements (see drawing 1, drawing 2) are applied to the cement or raw materials mixing even silo under Φ12 m. Annular zone aerating silo is installed inclining to the centre; the central area aerating silo is installed with horizontal level. C type (see drawing 3) is applied to the cement or raw materials mixing even silo up with a diameter over Φ12 m. Annular zone aerating silo is installed inclining to the centre; the central area aerating silo is installed with horizontal level. D type (see drawing 4) is applied to variable kinds of cement or raw materials mixing even silo. Annular zone aerating silo is installed inclining to the centre; the central area aerating silo is installed with horizontal level, but the central area is small. E type (see drawing 5) is applied to variable kinds of cement or raw materials mixing even silo. Annular zone aerating silo is installed inclining to the centre; the central area aerating silo is installed with horizontal level.F type (see drawing 5) is applied to different kinds of cement or raw materials mixing even silo. All the aerating silos are installed with horizontal level. Each of the six basic arrangements has its own advantages, disadvantages and applying scope, so the designer and user should choose the suitable ones according to the actual situation. The need of district number of the aerating silo should be based on the actual situation, however must be consistent with requirements of four, six, eight or twelve districts.

Order Information:

the specification of the even silo, dimension factor of the aerating silo, or the draft the bottom of silo layout should be provided in order to do a tailor-made design.