Feeder

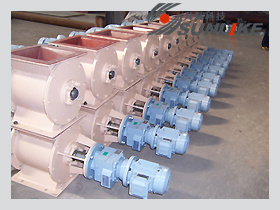

Feeder transport of materials according to the characteristics of a variety of different structural forms, has formed a standardized series. Common types and names are: B, QB in light apron feeder, DK, DB, PZ-type disc feeder; GW-type rigid impeller feeder and DG, LE-type single and double screw feeder.

Performance parameters of the feeding machine because of the change of material properties and process arrangement change, therefore accurate specifications, throughput, speed, power, etc should be determined by calculation. For powdery and granular materials can choose GW type rigid impeller feeder or DG, LE type single and double spiral feeder; For small block material can choose QB type apron feeder or DK, DB, PZ type disc feeder; Can be used for big block material B type apron feeder. Users can through the table below for preliminary selection, can also provide us with in and out of the mouth, throughput, transmission center distance and transportation distance, height, material name, blocks of the original parameters such as humidity requirements, to design scheme selection directly by the engineer to help you.

QB in the light plate feeder main performance parameter table

DK, DB, PZ disk feeder main performance parameters table