FU chain conveyor

Bulk material between each particle exist within the friction and the pressure inside, when conveying chain conveyor and its attachments when motion, bulk material in conveyor machine groove by and conveying movement direction whetherisolated tension, make bulk material particles between pressure inside, thus make bulk material within friction between increase. When this kind of friction within the greater than bulk material and machine chamfer of lateral friction, bulk material conveying chain will along the moving direction of the move, and increased the pressure inside guarantee the bulk material feeding between layers of steady state, thus formed the whole continuous flow, like water generally. (when the material ratio of height and machine chamfer can meet certain conditions, material flow is stable, feeding speed approximately equal to the chain speed).

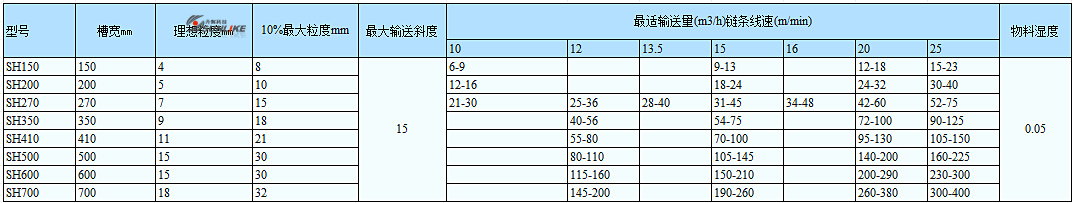

◎Big conveying capacity, and it can reach 15m3/h-600m3/h.

◎Long conveying distance, and a single conveyor can reach about 60m

◎Energy consuming is low. It can save 40%-60% compared to screw conveyor.

◎The full sealing brings no leakage. It can be operated safely, reliable running, and safe environment protecting.

◎Long using life. The conveying chain can be normally used for 5 years. The rollers’ life can be two or three years.

◎It can convey from two directions and can be arranged in the upper air, on the ground or in the holes.

◎The material can be discharged nimbly from many points. The process arrangement is nimble.

◎Low using fees and low maintenance rate.